Discontinuous PU, PIR Sandwich Panel Line

year

Discontinuous PU, PIR sandwich panel line

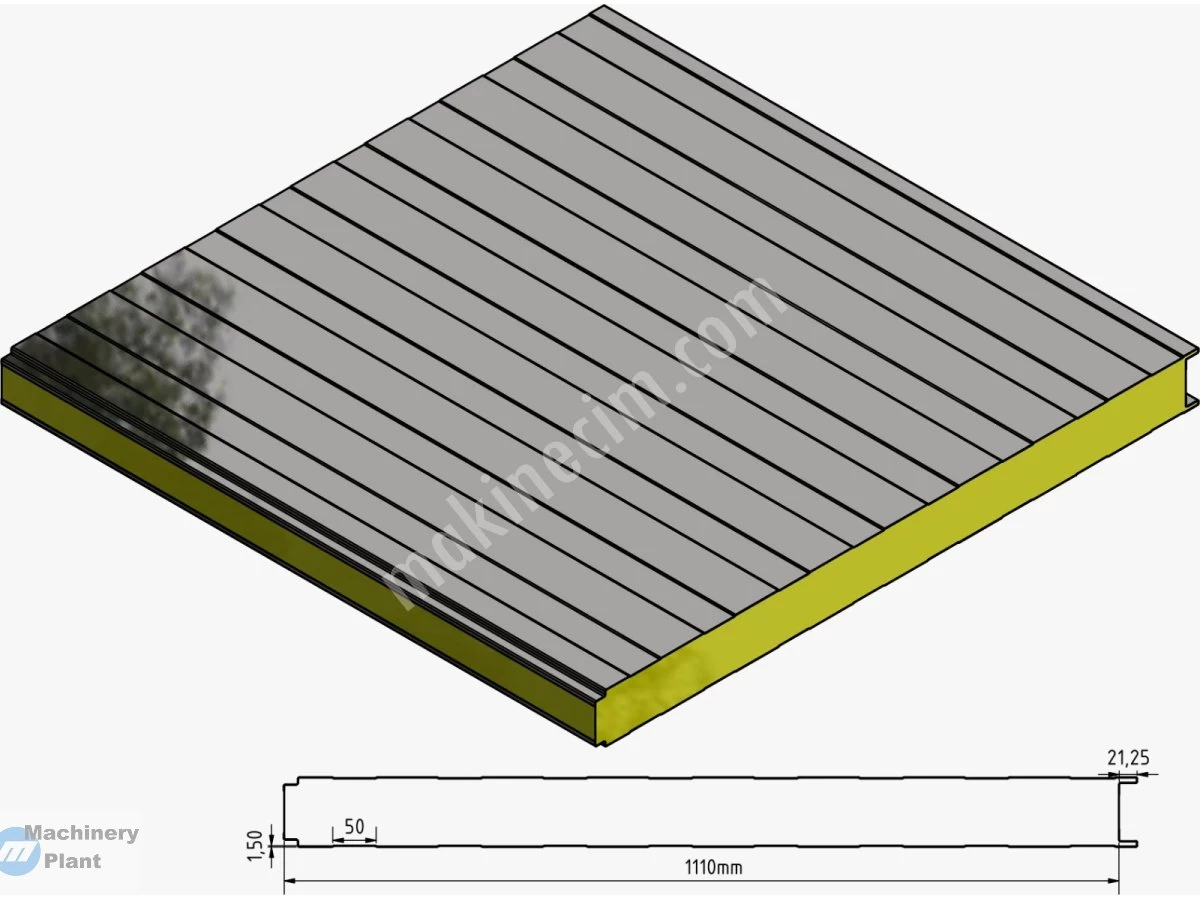

Discontinuous PU, PIR sandwich panel lines are widely used in the production of insulated building materials. These lines are capable of producing panels with different thicknesses, widths, and lengths. The panels are made of a core material sandwiched between two metal sheets. The core material is usually made of polyurethane (PU) or polyisocyanurate (PIR) foam. These materials have excellent insulating properties and are therefore ideal for use in construction.

Panel Production Process: The production process for discontinuous PU, PIR sandwich panels involves several steps. The first step is to prepare the metal sheets. This involves cleaning and coating the sheets with a primer to protect them from corrosion. The sheets are then cut to the required length and width.

The next step is to prepare the core material. The PU or PIR foam is mixed with a blowing agent and poured into a mold. The foam expands and fills the mold, creating a solid block. The block is then cut into panels of the required thickness.

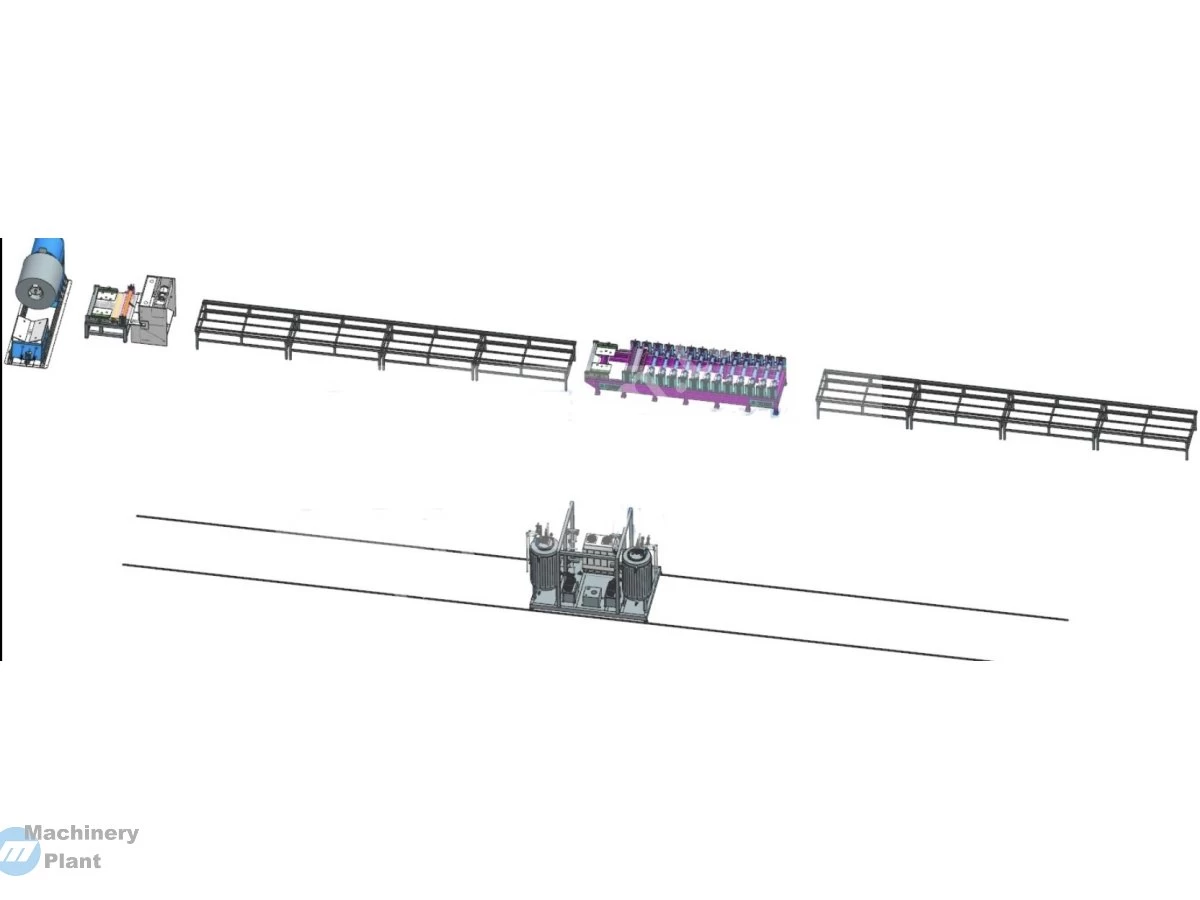

The metal sheets and the foam panels are then fed into the sandwich panel line. The line consists of a series of rollers and presses that bond the metal sheets to the foam core. The panels are then cut to the required length.

Advantages of Discontinuous PU, PIR Sandwich Panel Lines:

- Energy efficient: PU and PIR foam have excellent insulating properties, which makes the panels produced by discontinuous sandwich panel lines energy efficient. This can help reduce energy costs for buildings.

- Cost-effective: Discontinuous sandwich panel lines are cost-effective because they can produce panels in large quantities at a lower cost compared to other insulation materials.

- Lightweight: PU and PIR foam are lightweight materials, which makes the panels produced by discontinuous sandwich panel lines easy to handle and install.

- Versatile: Discontinuous sandwich panel lines can produce panels with different thicknesses, widths, and lengths, making them suitable for a variety of applications in the construction industry.

Conclusion: Discontinuous PU, PIR sandwich panel lines are an important part of the construction industry. They produce energy-efficient, cost-effective, lightweight, and versatile panels that are ideal for use in building construction. These panels offer excellent insulation properties and can help reduce energy costs for buildings. As the demand for sustainable building materials continues to grow, the use of discontinuous sandwich panel lines is expected to increase in the future.

Sandwich Panel Machine, Discondinued Sandwich Panel Machine, Panel Machine, Cold Storage Panel Machine, Roof Panel Machine, Çatı Paneli Makinası